Designed for temperatures up to -269 °C

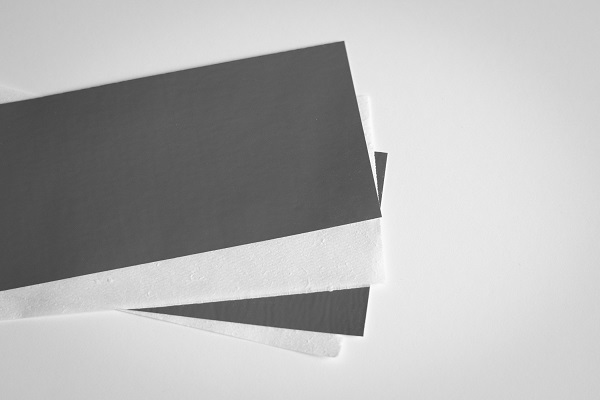

Thickness of single layer:

- Aluminum foil 0,0065mm

- Spacer 0,07mm

Single layer weight:

- Aluminum foil 18,0 g/m²

- Spacer 14,0±2,0 g/m²

Characteristic:

- Non-flammable, flame retardant, dedicated for flammable substances such as oxygen and LNG.

- Good pomping out conditions.

- It does not contain organic compounds or carbon, which allows it to be used in special research facilities.